Batteries serve as the vital power source for electric forklifts, constituting a critical component of their functionality. Common battery types include lead-acid batteries and lithium batteries, with lead-acid batteries further categorized as conventional and maintenance-free. Due to their high cost and complex shipping procedures, lithium batteries hold a slightly smaller market share than lead-acid batteries. The following outlines essential considerations regarding forklift batteries and guidelines for safe usage:

- Initialization of Lead-Acid Batteries When the battery is freshly charged, it is imperative to lift and lower the forklift mast 3-5 times before starting the forklift to prevent excessive floating voltage that could damage the electronic control card.

- The lifespan of Lead-Acid Batteries The lifespan of lead-acid batteries should not be less than 350 cycles when discharged to 75% of their capacity.

- Pros and Cons of Lead-Acid Batteries

- Pros: Economical pricing, approximately 1/4 to 1/6 of the cost of other battery types.

- Cons: Large weight and volume, low energy-to-weight ratio, and strict requirements for charging and discharging.

- Monthly Full Discharge for Batteries For lead-acid batteries that remain in a partially discharged state for extended periods, a complete discharge should be performed monthly to maintain the activity of the battery plates.

- Factors Detrimental to Batteries Numerous factors adversely affect batteries, primarily during the charging and discharging stages. These include prolonged discharge currents exceeding permissible values and exceeding the allowed discharge capacity; During the charging phase, overcharging and undercharging are common issues. Other factors are also mostly caused by human factors such as selection, usage maintenance, rationality of controllers and chargers, and timely detection of battery faults.

- Causes of Battery Overheating Battery overheating may result from excessive discharge currents, attributed to factors such as overloaded loads, vehicle resistance, steep slopes, insufficient battery capacity, motor issues, and power transmission line problems. Insufficient battery capacity is a leading cause of battery overheating, necessitating an increase in capacity to reduce operating currents.

- Detrimental Effects of Battery Heating While minor heating is permissible during use and charging, abnormal heating is not tolerated. Excessive heating leads to the evaporation of electrolyte water, reduced charging efficiency, plate deformation, increased internal resistance, accelerated oxidation of mechanical components, and ultimately results in decreased battery capacity and shortened lifespan.

- Can Distilled Water be Added to Batteries? Valve-regulated maintenance-free lead-acid batteries differ from other batteries, as they cannot be entirely maintenance-free, only reducing the workload. When the capacity significantly decreases, adding a suitable amount of water is advisable to restore the original electrolyte concentration or maintain it slightly below the original concentration, benefiting the battery plates.

Guidelines for Safe Battery Usage:

- Regular Inspection

- Liquid Level: Ensure the electrolyte level is maintained, as levels below the rated capacity can shorten the battery’s lifespan and cause overheating damage.

- Terminals, Wires, and Caps: Regularly inspect corrosion at battery terminal junctions and wire connections, and check for deformations or heating of caps.

- Appearance: Keep the battery surface clean to prevent leakage.

- Maintenance

- Water Addition: Add distilled water according to specified levels, avoiding excessive water addition that could lead to leakage.

- Charging: Gases are produced during the charging process, necessitating well-ventilated charging areas without open flames. Oxygen and acidic gases produced during charging can impact the surrounding environment. Unplug the charging plug only after turning off the charger. After charging, hydrogen gas lingers around the battery; hence, avoid open flames and open the battery cover for ventilation.

- Maintenance of Terminals, Wires, and Caps: Professional technicians designated by the manufacturer should conduct maintenance.

- Cleaning: If minimally dirty, wipe the battery surface with a damp cloth; if heavily soiled, remove the battery from the vehicle, wash it with water, and allow it to air dry.

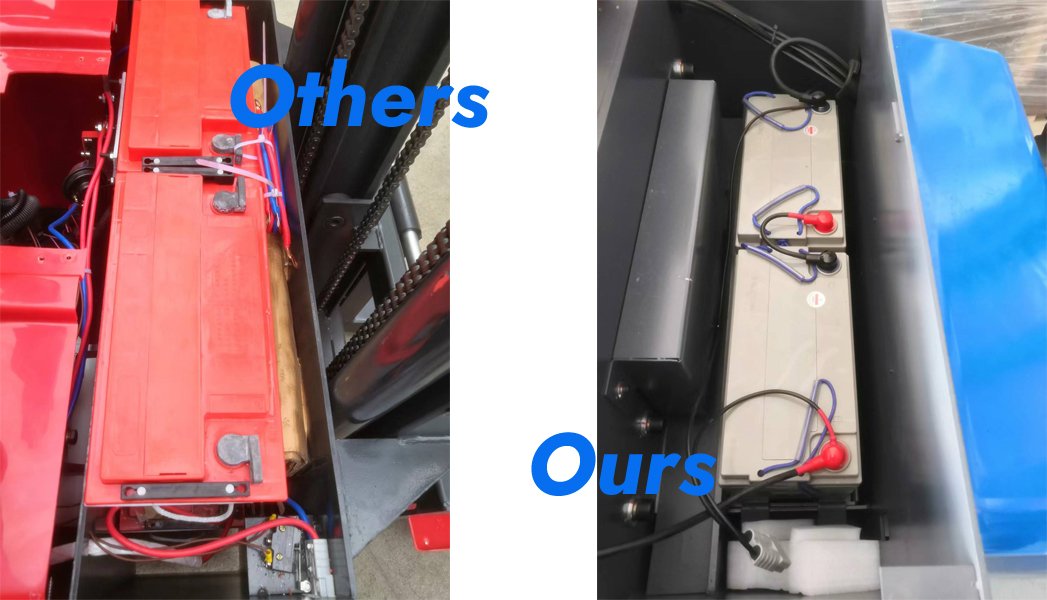

Union Forklift is committed to providing outstanding logistics solutions, and our choice of high-quality lead-acid batteries as the power source for our forklifts, coupled with the use of professional wiring equipment, reflects our dedication to ensuring equipment reliability and longevity. This commitment extends beyond achieving excellent performance to a focus on customer satisfaction. Choose Union Forklift for the perfect combination of reliability and performance.

To learn more about these machines, visit the official website https://unionforklift.com/